ZB 460RS

Fully Automatic Roll-feeding Paper Bag Making Machine

ZB360RS Fully automatic roll feeding paper bag making machine, use roll paper as raw material, combined with handle reinforced paper and paper twist rope, to realize fully automatic production of paper bags with twist rope or flat handle, This machine adopts PLC and motion controller, servo drive control system, intelligent operation interface, realize high speed production and high efficiency.

lt is an ideal equipment for producing shopping bag such as food and clothing packaging.

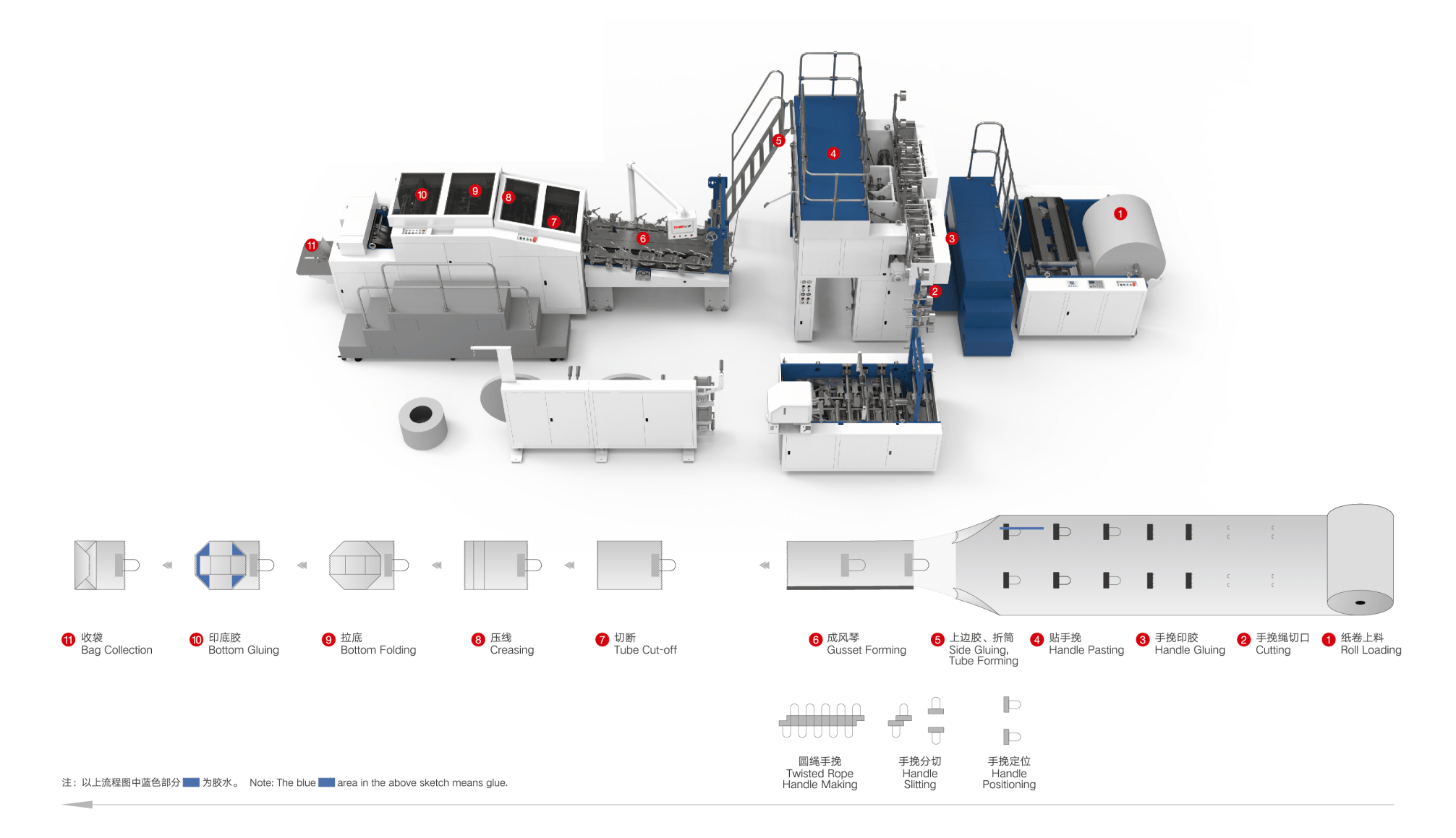

The production process of this machine is: roll feeding, paper handle pasting, tube forming, tube cutting, bottom creasing, bottom gluing, bottom pasting, output.

(▲You can click the picture see the machine work flow in youtube)

Kraft paper, coated paper (including laminated paper)

|

|

|

|

|

| Paper Roll Width | 550-1170mm | 550-1170mm | |

| Max.Paper Roll Diameter | Φ1200mm | Φ1200mm | |

| Core Diameter | Φ76mm(3″) | Φ76mm(3″) | |

| Paper Thickness | 80--170g/m^2 | 60--170g/m^2 | |

| Bag Body Width | 200-360mm | 200-360mm | |

| Paper Tube Length | 260-550mm | 260-650mm | |

| Bag Bottom Size | 60-210mm | 60-210mm | |

| Handle Rope Height | 100-120mm | - | |

| Handle Rope Diameter | Φ4-6mm | - | |

| Handle Patch Length | 152.4mm | - | |

| Paper Rope Center Distance | 76mm | - | |

| Handle Patch Width | 50mm | - | |

| Handle Patch Roll Diameter | Φ1200mm | - | |

| Handle Patch Roll Width | Φ100mm | - | |

| Paper Patch Thickness | 100-180g/m^2 | - | |

| Max Production Speed | 130bags/min | 170bags/min | |

| Total Power | 42KW | ||

| Overall Diamension | 12500*5000*3300 | ||

| Total Weight | 21500KGS | ||

| No. | Name | Origin | Brand | No. | Name | Origin | Brand |

| 1 | Servo motor | Japan | Mitsubishi | 8 | Photoelectric sensor | Germany | SICK |

| 2 | Frequency converter | France | Schneider | 9 | Metal proximity switch | Korea | Autonics |

| 3 | Button | France | Schneider | 10 | Bearing | Germany | BEM |

| 4 | Electric relay | France | Schneider | 11 | Hot melt glue system | USA | Nordson |

| 5 | Air switch | France | Schneider | 12 | synchronized belt | Germany | Contitech |

| 6 | Frequency converter | France | Schneider | 13 | Remote Controller | China Taiwan | Yuding |

| 7 | Power switch | France | Schneider |

By continuing to use the site you agree to our privacy policy Terms and Conditions.