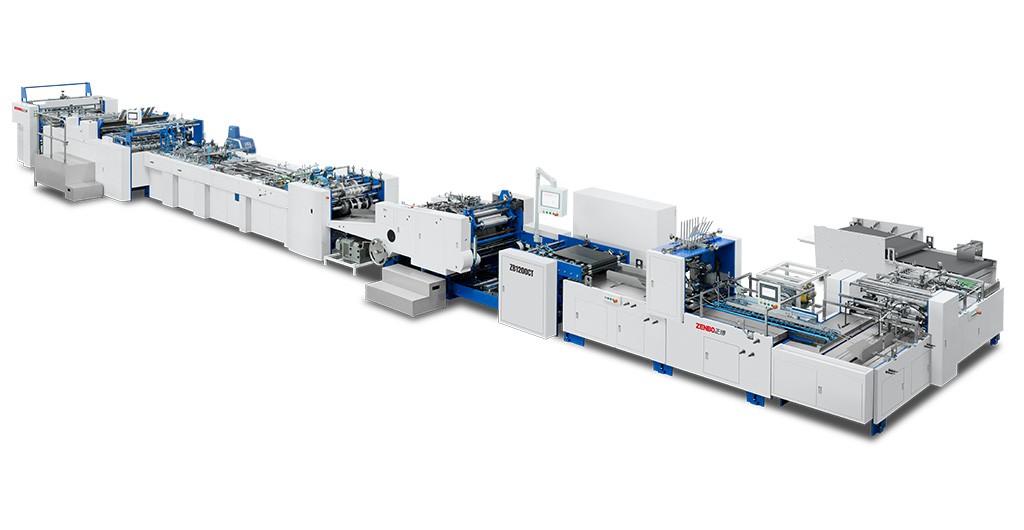

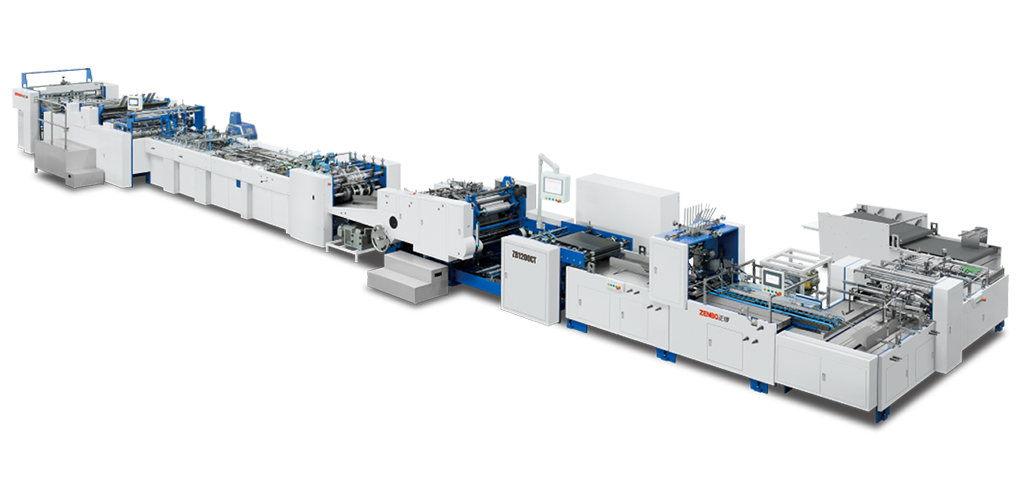

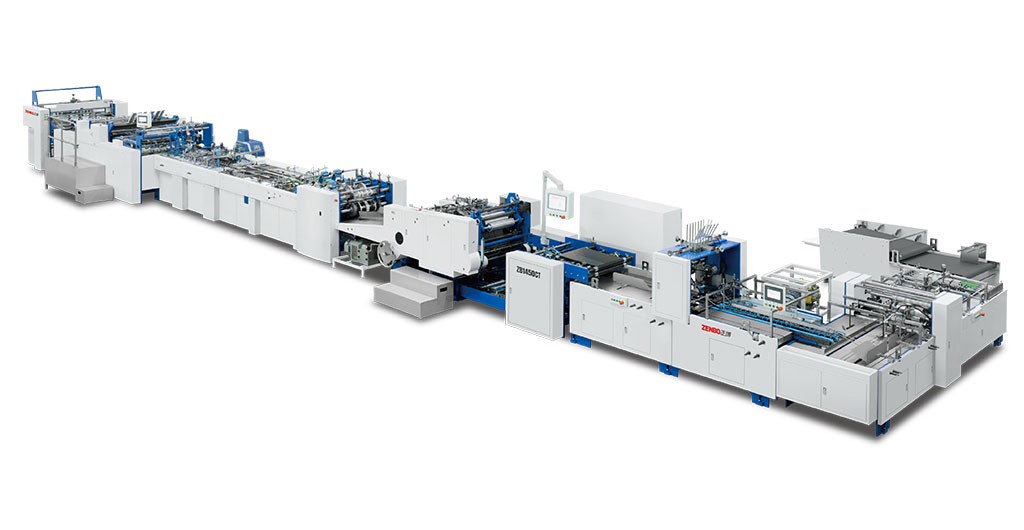

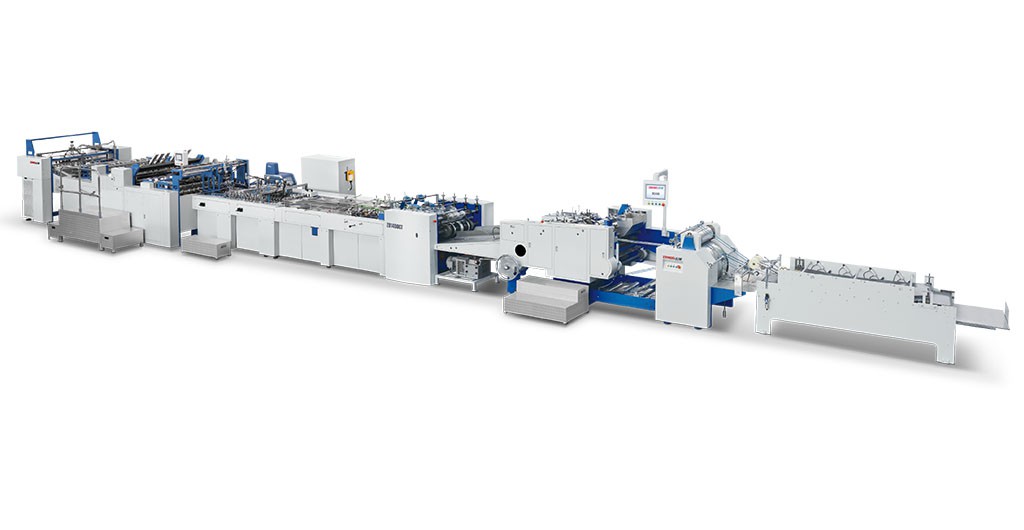

ZB 1200CT-430S

Fully Automatic Sheet-feeding Paper Bag Making Machine

ZB1200CT-430 Automatic sheet feeding paper bag making machine (independent innovation), possess a large number of independent patents, create the high-speed automatic paper bag production.

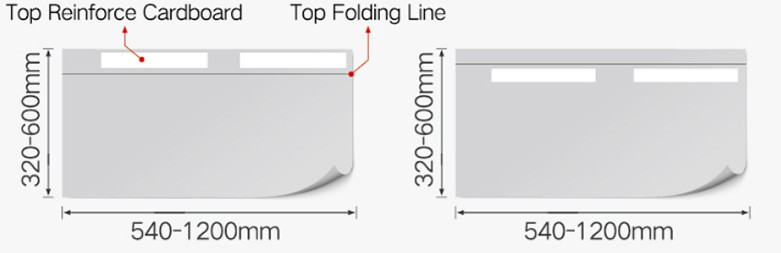

This machine adopts servo system for top reinforced card taking, realize the top reinforced card paste position adjustable. New “half-blade” device ensure bag body trackless. Adopts with PLC and Servo control system, reserve of extensible intelligent port for future system upgrades and remote services.

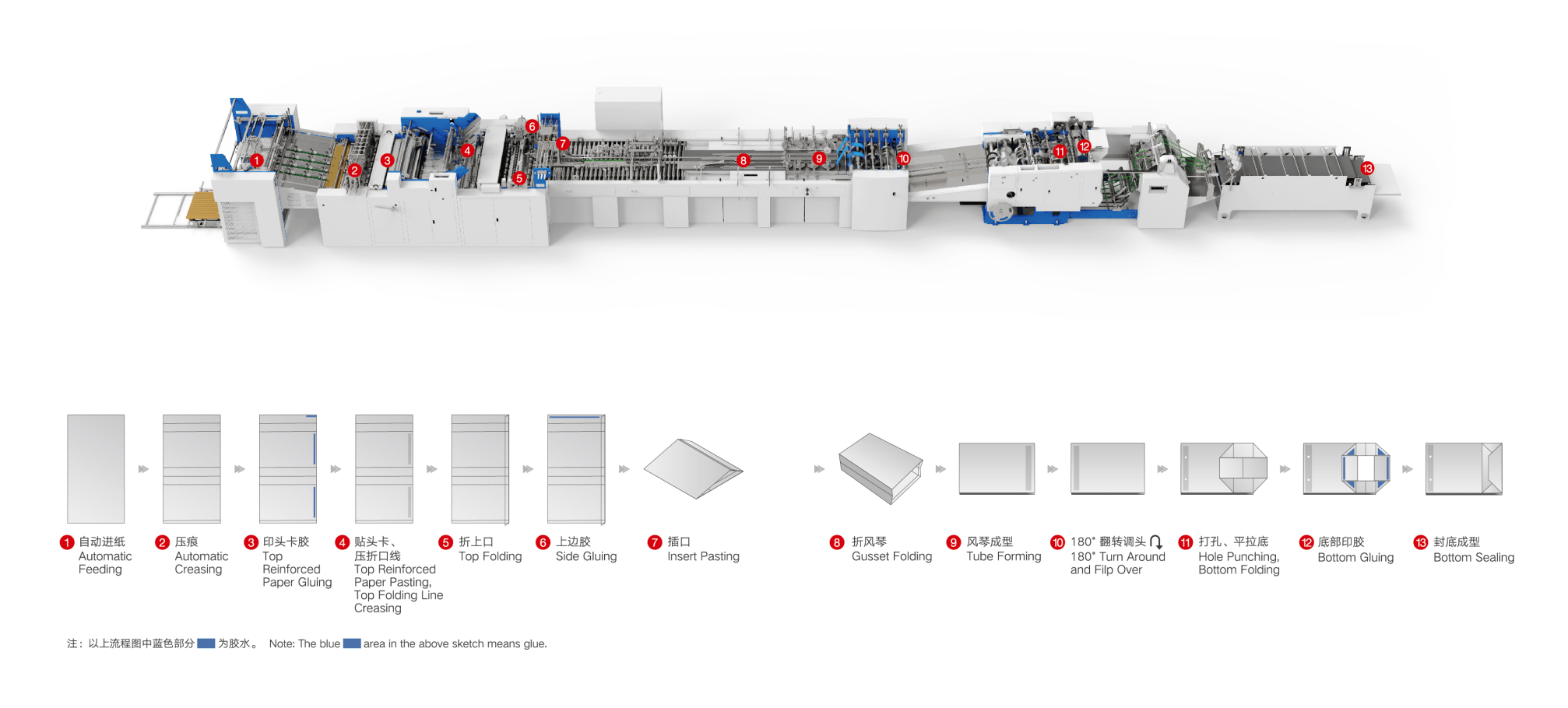

The basic working flow is sheet feeding, creasing, servo top reinforced card taking and pasting, top folding (insert pasting), tube forming, gusset forming, bottom open and gluing, bottom folding and closing, compaction and output.

All these steps increase the bag making efficiency and reduce the setup time, save a lot of labor cost for top reinforced card pasting. Realize automation, intelligent and high efficiency production requirement.

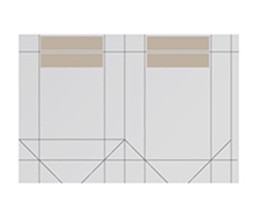

The glue position is on the big side (bag surface)

Automatic Bottom Cardboard Inserting

|

Max.sheet (LX W) |

1200 x600mm |

|

Min.sheet (LX W) |

540 x 320mm |

|

Sheet weight |

120-250g/㎡ |

|

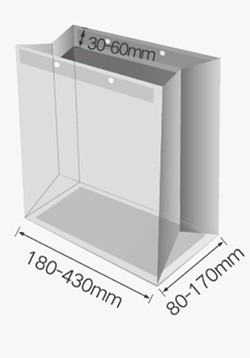

Top folding width |

30-60mm |

|

Paper Bag Tube Length |

280-570mm |

|

Bottom Width(Gusset) |

80-170mm |

|

Bag Width |

180-430mm |

|

Top Reinforce Cardboard Weight |

200-500g/㎡ |

|

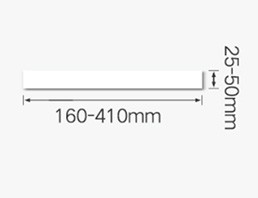

Top Reinforce Cardboard Length |

160-410mm |

|

Top Reinforce Cardboard Width |

25-50mm |

|

Bottom Cardboard Weight |

---- |

|

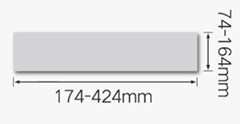

Bottom Cardboard Width |

---- |

|

Bottom Cardboard Length |

---- |

|

Speed |

40-70 bags/min |

|

Machine Size |

22000*3400*1800mm |

|

Total/Production Power |

40/20kw |

|

Voltage |

380V |

|

Total Weight |

16T |

|

Glue Type |

Water Base Glue And Hot-melt Glue |

| No. | Name | Origin | Brand | No. | Name | Origin | Brand |

| 1 | Feeder | China | RUN | 12 | Bearing | Germany | BEM |

| 2 | Main motor | China | Fangda | 13 | Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 14 | Synchronize belt | Germany | Continental |

| 4 | Frequency converter | France | Schneider | 15 | Air pump | Germany | Becker |

| 5 | Button | Germany |

Eaton Moller |

16 | Pneumatic component | Taiwan/Japan | Airtac/SMC |

| 6 | Electric relay | Germany | Weidmuller | 17 | Pilot valve | Taiwan/Japan | Airtac/SMC |

| 7 | Air switch | Germany |

Eaton Moller |

18 | Photoelectric switch | Korea/Germany | Autonics/Sick |

| 8 | AC contactor | Germany |

Eaton Moller |

19 | Hot melt glue system | America | Nordson |

| 9 | Wiring terminal | Germany | Weidmuller | 20 | Servo motor | Taiwan | Delta |

| 10 | Touch screen | Taiwan | Weinview | 21 | Servo gear box | Japan | Desboer |

| 11 | Switching Power Supply | Taiwan | MW |

Fully Automatic Sheet-feeding Paper Bag Making Machine

F Series Customizedachine

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Sheet-feeding Paper Bag Making Machine

Automatic Sheet-feeding Paper Bag Making Machine

By continuing to use the site you agree to our privacy policy Terms and Conditions.